Fire hazard analysis (FHA) is a method of evaluating fire and explosion hazards present and the subsequent potential consequences of loss-of-containment or fire scenarios at a processing plant or storage facility that requires an in-depth assessment of fire risk due to significant quantities of flammable materials. These assessments are based on specific review criteria that are dependent upon the types of hazards being assessed, as well as commodities stored and facility processes.

FLAMMABLE AND COMBUSTIBLE LIQUIDS FIRE HAZARD ANALYSIS

Facilities that transfer, store, process, or handle quantities of flammable and combustible liquids beyond threshold limits are often required by an Authority Having Jurisdiction (AHJ), or an insurer, to have a Fire Hazards Analysis (FHA) completed in accordance with NFPA: 30 Flammable and Combustible Liquids Code. To provide a comprehensive FHA, including hazard identification and risk assessment for the facility, a fire protection engineer reviews the following items in detail:

- Fire risk likelihood

- Fire and explosion consequence analysis

- Vessel pressure relief

- Overall facility arrangement

- Local conditions

- Containment

- Site incident mitigation features

- Emergency management procedures

- Local first responder capabilities

- Additional National Fire Protection Association codes and standards requirements applicable to each facility

Final reports typically include information related to the analysis techniques, methodologies and modeling results, as well as findings related to fire hazards and or fire scenarios modeled and corresponding risk mitigations in place (passive fire protection, active fire protection, process safety features, emergency response, etc.).

WHAT ARE THE OTHER COMMON HAZARD IDENTIFICATION AND ANALYSIS?

Each hazard assessment will have its own unique approach based on related fire codes, industry standards, regulatory compliance, and specific process hazards at varying facility types. The items listed for the example analyses below include only a sample of the items required to be evaluated for a complete and code compliant evaluation and final report. A critical initial step in performing an analysis is to identify the types of fire and explosion hazards that are specific to the facility.

LIQUEFIED PETROLEUM GAS (LPG) FIRE SAFETY ANALYSIS

Facilities utilizing LPG storage vessels with an aggregate water capacity greater than 4,000 gallons are typically required to have a Fire Safety Analysis (FSA) completed by a licensed engineer. This type of analysis is completed in accordance with NFPA: 58 Liquefied Petroleum Gas Code. To provide a comprehensive FSA, Vertex evaluates the following hazard and mitigation features:

- Control and safety features

- Valves and transfer piping

- Equipment specifications

- Protection against local hazard conditions (inclement weather)

- Control of ignition sources

- Hazards to off-site populations and properties

- Hazards from other industrial operations

- Emergency management procedures

- Additional NFPA codes and standards requirements applicable to each facility

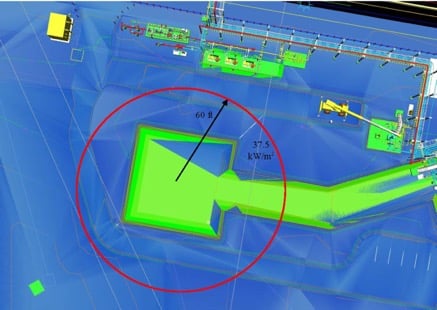

Consequence Modeling

Beyond identification, modeling is sometimes required to determine thresholds and limits of a consequence for an incident relating to certain hazards and risks. Vertex’s engineering and design staff are experienced with modeling a variety of incidents including liquids and gaseous releases, fire incidents (pool fire, jet fire, etc.), blast and explosion overpressure, vapor dispersion, and other types of modeling as required for each hazard. Software used is dependent on the incident and desired information output; however, the following are commonly used tools:

- PyroSim (Front End Software for Fire Dynamics and Smoke Control Simulator)

- FDS (Fire Dynamics Simulator)

- PHAST – DNV GL (Process Hazard Analysis Software)

- BREEZE

- NRC Hazard Calculation Tools

To learn more about VERTEX Fire Protection and Engineering services visit our Fire Protection Engineering service page or submit an inquiry here.